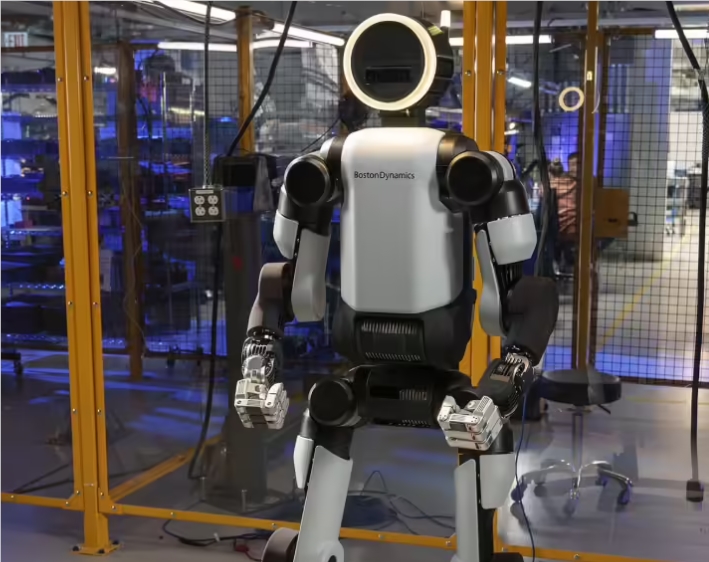

Meet Xiao Mo: The Humanoid Robot Transforming Battery Production

Robotics Breakthrough at CATL Factory

The hum of machinery at CATL's Zhongzhou base now includes a new sound - the precise movements of humanoid robots working alongside human technicians. In what industry experts are calling a watershed moment for industrial automation, these robots named 'Xiao Mo' have taken over some of the most dangerous and delicate tasks in battery production.

Handling High-Voltage Challenges

What makes Xiao Mo's deployment particularly impressive is its handling of end-of-line functional testing (EOL) and DC internal resistance testing (DCR). These processes involve working with hundreds of volts - operations traditionally requiring skilled human workers wearing protective gear. "The high-voltage plug-in operations were our biggest safety concern," explains a CATL production manager. "Now we're seeing sparks disappear completely from these workstations."

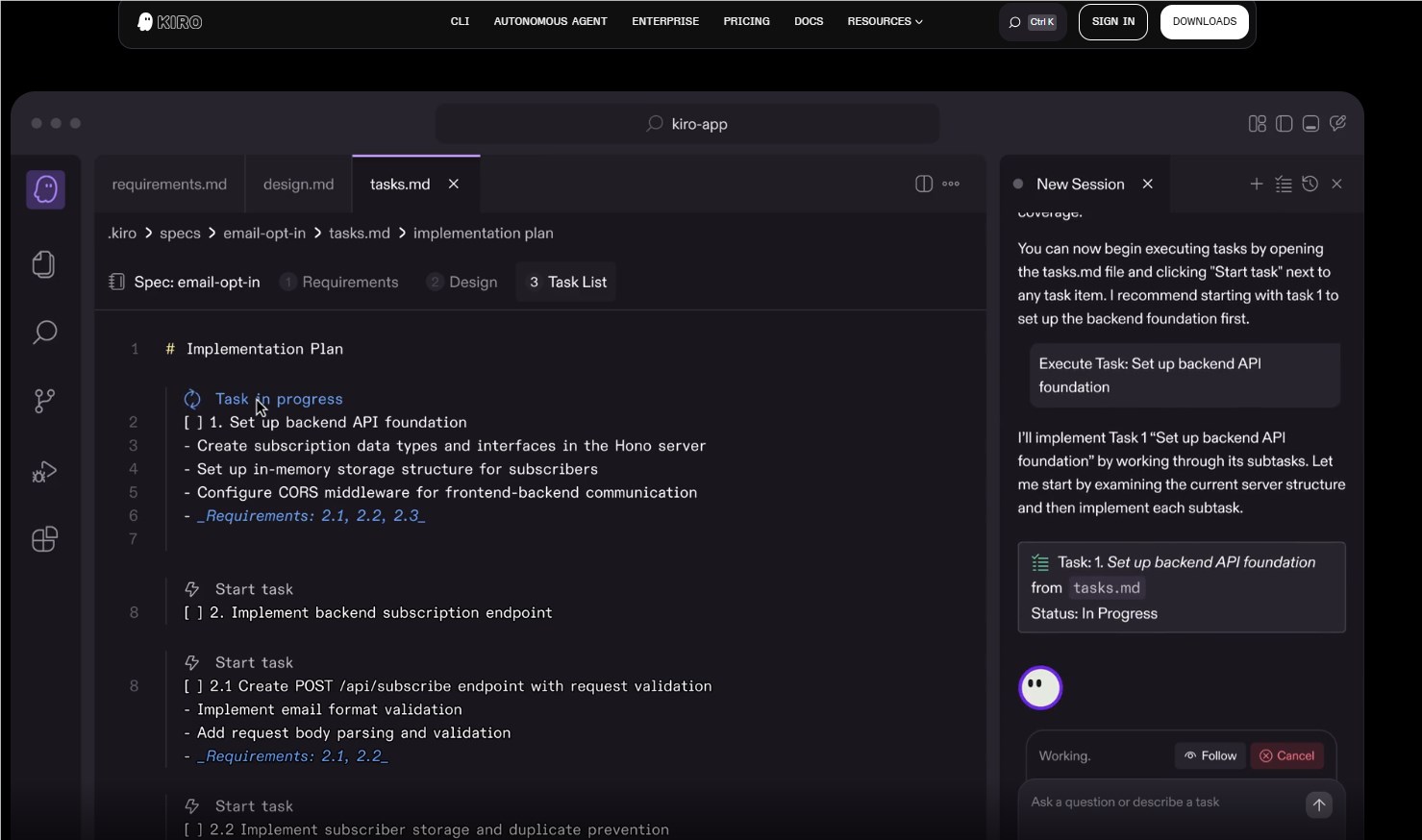

The robot doesn't just improve safety - it's remarkably efficient. Workers report Xiao Mo completes three times the daily workload compared to manual operations, with plug-in success rates consistently above 99%. This reliability comes from advanced vision-language-action (VLA) modeling, allowing the robot to adapt to material positioning variations and adjust force dynamically when handling flexible cables.

The Brains Behind the Bot

Qianxun Intelligence, the startup behind Xiao Mo, has made waves in robotics circles despite being less than a year old. With three funding rounds totaling over 1.1 billion yuan in 2024 alone, the company represents China's growing prowess in embodied intelligence technology.

Led by former Luoshi Robotics CTO Han Fengtao and backed by CATL affiliate Buir Capital, Qianxun aims ambitious goals for 2025: collecting one million hours of operational data and scaling production to hundreds of units. "We're not just building demonstration models," says a Qianxun engineer. "These are tools designed for real factory floors."

The Future on Factory Floors

As morning shifts begin at Zhongzhou base, workers no longer approach certain stations with caution tape warnings. Instead, they collaborate with their robotic counterparts - one example of how automation is evolving beyond isolated machines to integrated team players.

The success at CATL suggests we may be turning a corner in industrial robotics. Rather than replacing human workers entirely, technologies like Xiao Mo demonstrate how robots can take on dangerous tasks while humans focus on oversight and quality control.

Key Points:

- Safety breakthrough: Eliminates risks from high-voltage operations

- Unmatched precision: Achieves 99%+ success rate in delicate procedures

- Production boost: Handles triple the workload of manual processes

- Adaptive intelligence: Uses VLA modeling to adjust to real-world variables